Energy management

Implement energy information management system, Support multi-dimensional energy efficiency analysis. Take the main energy-consuming injection molding production line as an example, from 2018 year-to-date, XX The energy consumption of injection molding unit in the factory has decreased 38. 9%.

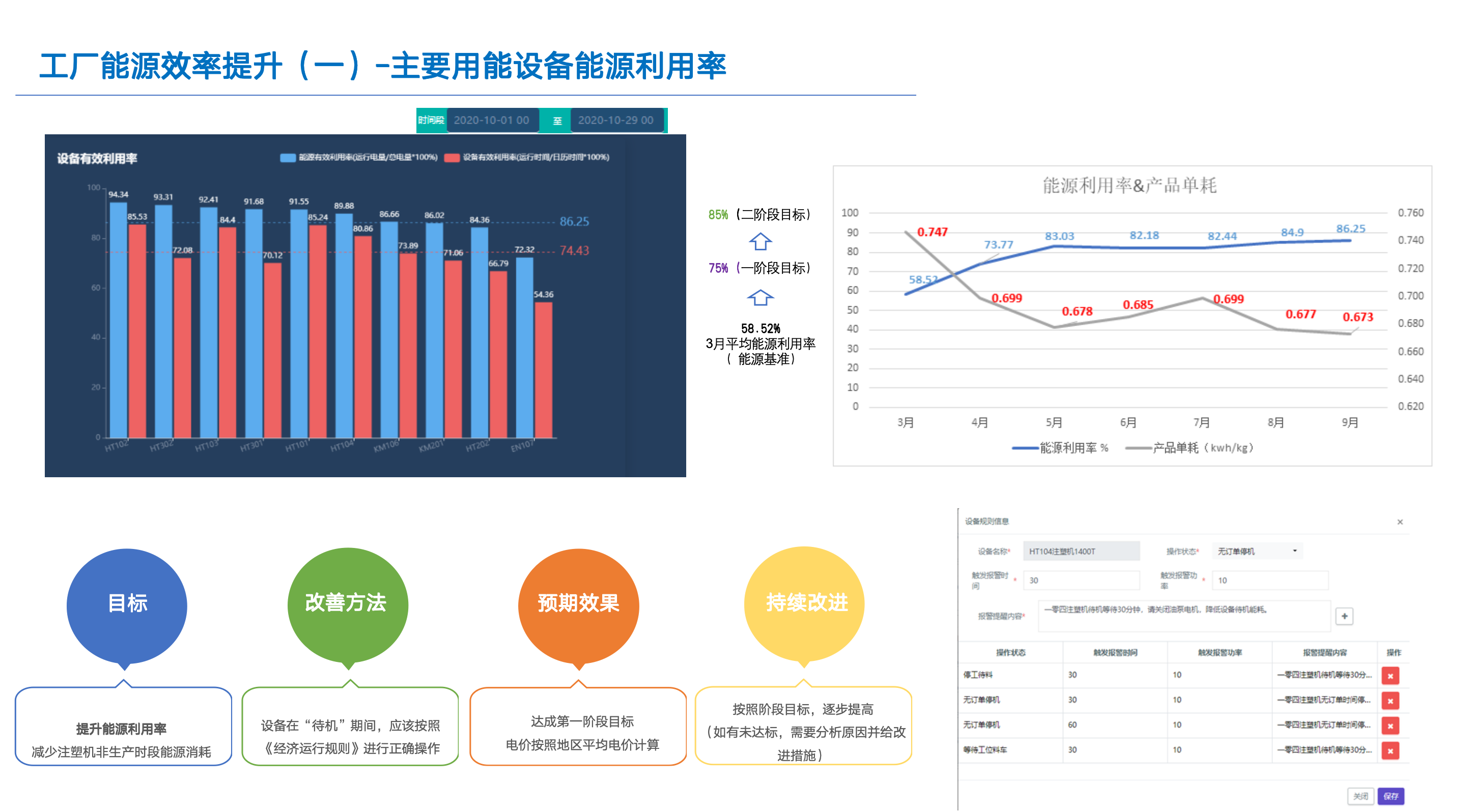

Plant digital energy Management

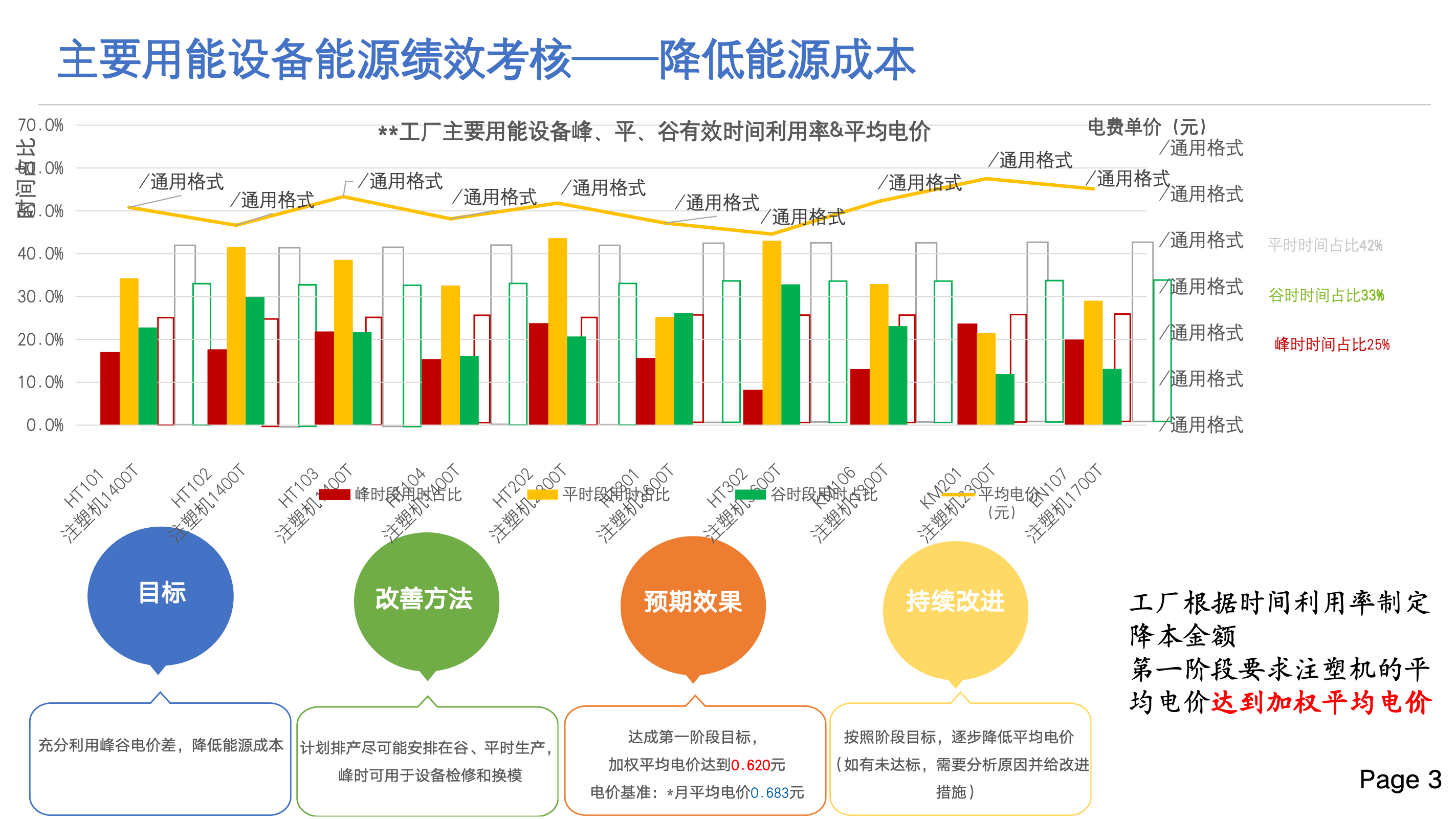

Mainly use energy equipment energy performance assessment——Reduce energy costs

The factory sets the cost reduction amount according to the time utilization rate

The first stage requires the average electricity price of the injection molding machine to reach the weighted average electricity price

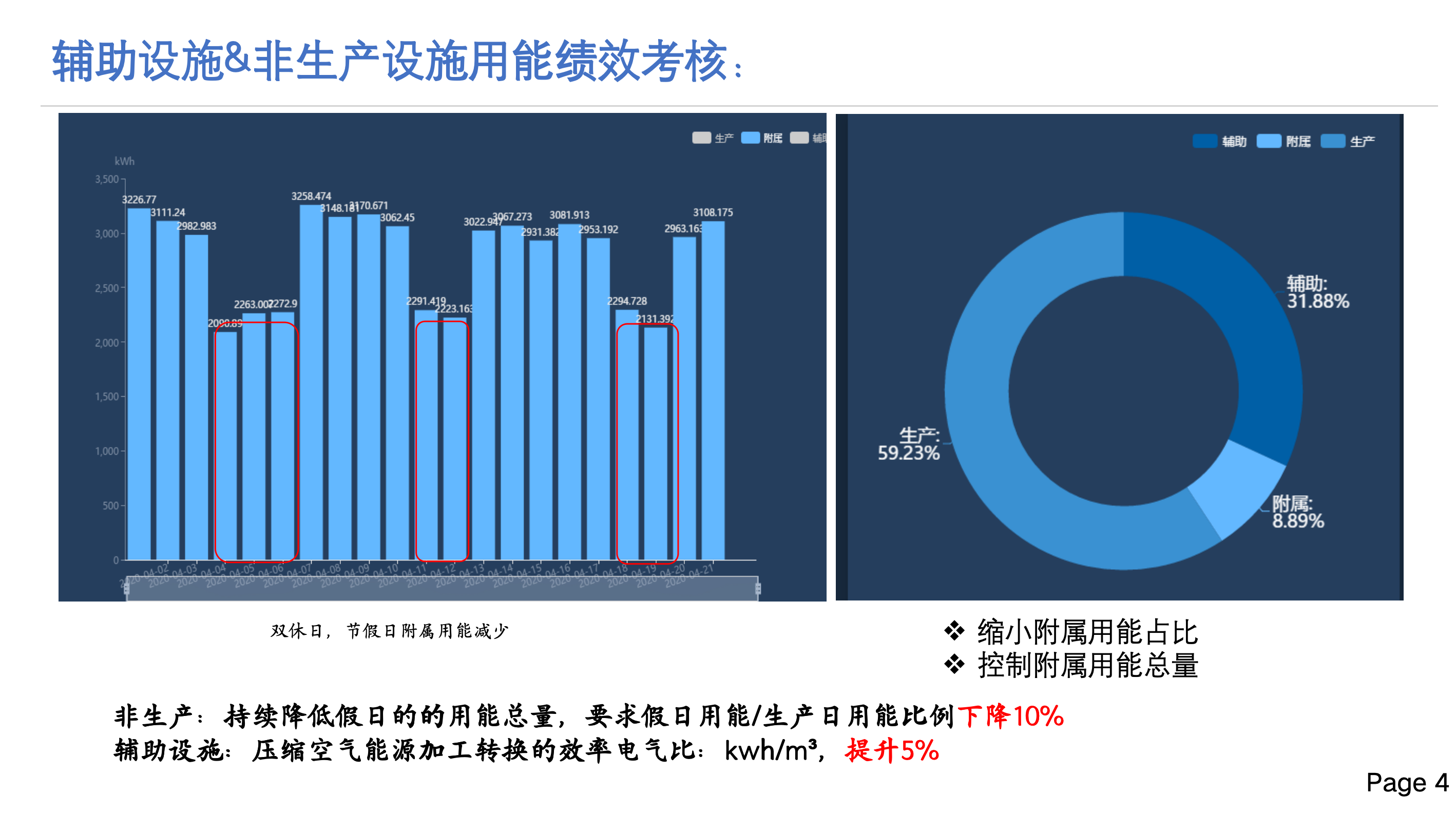

Auxiliary facility&Performance assessment of energy use in non-production facilities:

non-production: Continue to reduce total holiday energy use, Demand holiday energy/The proportion of daily energy production decreased 10%

Auxiliary facility: Efficiency electrical ratio of compressed air energy processing conversion: kwh/m³, Up 5%