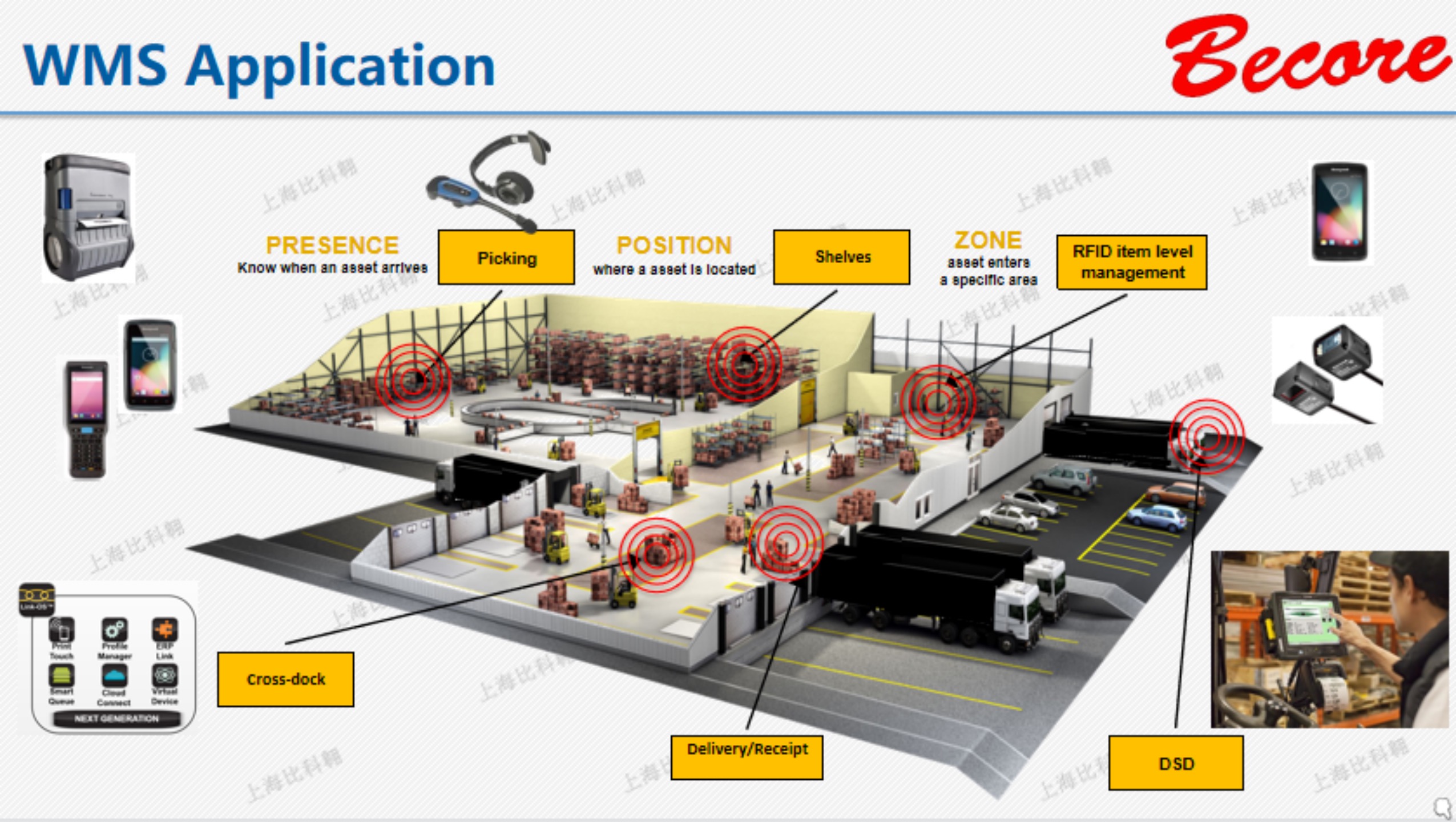

Warehousing logistics

In the field of warehousing logistics, Adopt Internet of things technology to achieve mass management, Can comprehensively improve the warehouse receipt, inventory, Outbound review, Product positioning, Storage location management and other business efficiency, Greatly improve the utilization rate of warehouse space, Effectively reduce labor costs. The final realization of high degree of data visualization, Help warehouse operators understand current operating status

Detailed introduction

Inventory accuracy

-

Difficult material management

Materials exist in a variety of packaging, Such as disk, slice, In bulk; Cannot be used individually, To be the whole package, The whole plate, The whole volume of recipients; Various specifications and models, Indistinguishable to the naked eye; Bulk components are not easy to count, Inventory in and out of storage is prone to error, Inventory cycle is also long. Costing is also difficult.

Batch management requirements are high

Inventory product parameters have volatility, Even if the same model product, Different delivery lots, The stability is different, For quality control, Strict batch management is required; Material distribution must be controlled in the same batch, Variety of raw materials, Batch matching sets, High requirements for material management.

Warehouse manual management, The material gathered much, Rare errors often occur, Or the material specification issued/Of the goods/The number of mistakes, Cause inconsistent accounts; When the location of material storage changes frequently, I often can't find the goods, Affect the efficiency of warehouse operations, The inventory is inaccurate.

Project value:

Inventory accuracy

Items in and out of storage, The warehouse keeper knows the specific quantity and balance quantity in real time through the system; The warehouse management system supports both a dial-in and a holistic approach , Take stock of materials periodically or irregularly, do "zhang, things, card" consistent; Materials can be stored by location, Accurate storage.

The whole process bar code management

throughHandheld wireless terminals are easy to carry, Anytime, anywhere, Instant data updates automatically, Fast and accurate, Reduction of human error.

Set and batch management

The system provides the analysis of the lack of material, Prevention can be done beforehand, Confirm the condition of all materials, Avoid downtime waiting for materials; At the same time the system inventory in the warehouse, Batch numbers can be automatically brought out according to fifO rules, Ensure the quality of incoming and outgoing materials, Achieve through the product batch number, Do source tracing, Ensure product quality!

Vocollect Intelligent speech picking solution, Optimize the warehouse picking route, Pick up the list to achieve multiple single merger picking

The higher the order overlap, The more obvious the efficiency improvement!